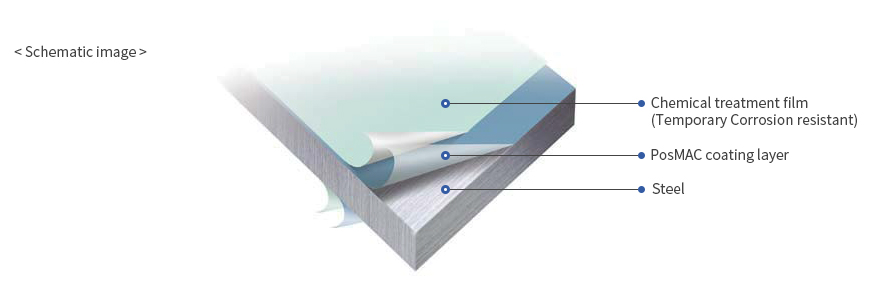

- - PosMAC은 포스코 자체 기술로 개발한 내식성이 높은 삼합금 코팅강(Zn-94.5%, Mg-3%, Al-2.5%)이다.

- - PosMAC은 동일한 코팅중량의 일반 용융아연도금강판(GI, GI(H)보다 5~10배 강한 내식성 제품이다. PosMAC은 단면부식성이 우수하여, 일반 두꺼운 도금 제품을 이 제품으로 대체할 수 있다.

- - GI와 동일한 공정, 조립, 도장 과정을 PosMACAS에도 적용할 수 있다.

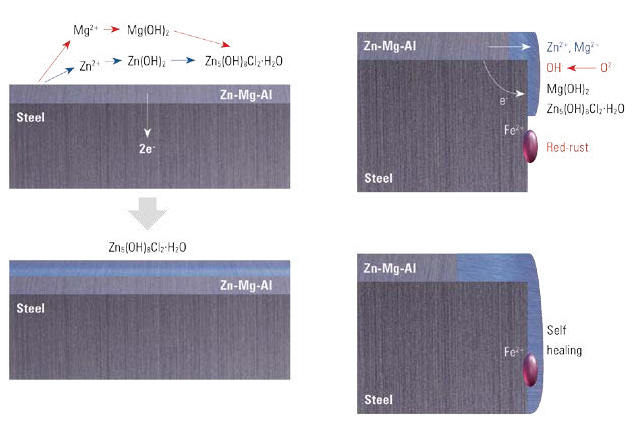

- - posMAC 코팅층의 마그네슘(Mg)은 매우 안정적인 "Simonkolleite"라고 불리는 고밀도 부식 생성물의 형성을 가속화할 것이다. 사이먼콜라이트가 막 형태의 코팅층 표면에 형성되면 염기 금속의 부식 억제제 역할을 한다.

- - 또한, 단면을 덮고 안정적인 부식 제품의 성장을 가속화하기 위해 상부 코팅 층을 용해할 수 있습니다. 그러나 이미 노출된 강판에서 붉은 녹이 발견될 수 있지만 튜닝의 경우 부식 생성물의 막이 단면을 덮고 부식을 방지하는 역할을 한다.

- - PosMAC은 평탄한 표면에서 아연도금강판에 비해 5~10배 내식성을 보인다.

- - 또한 PosMAC은 평평한 표면에서 갈발룸에 비해 내식성이 같거나 더 높습니다.

| CCT | GI(H) | Galvanume | PosMAC | |||||

|---|---|---|---|---|---|---|---|---|

| 양쪽의 코팅 중량 | 120g/㎡ | 200g/㎡ | 300g/㎡ | 600g/㎡ | 100g/㎡ | 140g/㎡ | 200g/㎡ | 275g/㎡ |

| 10 cycle (80Hr) |

||||||||

| 70 cycle (560Hr) |

||||||||

| 120 cycle (960Hr) |

||||||||

- - PosMAC은 또한 처음에 야외에 노출되었을 때 단면에 붉은 녹이 슨다. 그러나 시간이 지남에 따라 부식이 일어난다. PosMAC의 (붉은 녹) 면적은 특유의 산화물 기반 물질(시몬콜라이트)의 형성을 통해 감소하는 경향이 있다.

| Sample | Thickness | Coating weight (g/㎡) |

Cross-section image | ||

|---|---|---|---|---|---|

| After 6 months | After 1 years | After 2 years | |||

| PosMAC | 1.2 | 130 | |||

| 1.6 | 120 | ||||

| 2.0 | 300 | ||||

| Galvanume | 1.6 | 120 | |||

| GI(H) | 1.6 | 180 | |||

| 품질품목 | PosMAC | GI(H) | 갈바륨 | |

|---|---|---|---|---|

| 코팅층의 경도(Hv) | 110~130 | 60~80 | 80~100 | |

| 마찰 특성 | ◎ | X | △ | |

| 내식성 | Flat sheet | ◎ | △ | ◎ |

| 구부러짐 | ◎ | △ | △ | |

| 컵 | ◎ | △ | ◎ | |

| 횡단면 | ◎ | △ | X | |

| 내화학성 | ◎ | △ | △ | |

| 용접성 | ◎ | ◎ | ◎ | |